MEMS & Nanoengineering

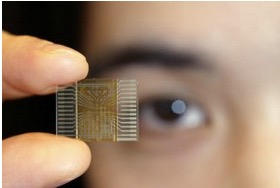

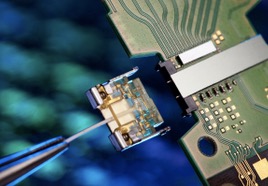

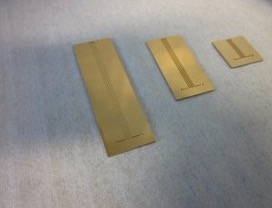

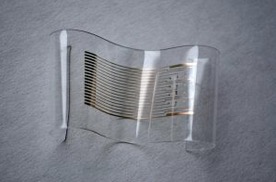

Micro-electro-mechanical-systems (MEMS) are miniaturized, integrated systems that contain transducers to transform physical/chemical/biological events input into electronic signals, and vice-versa. They represent all the ultra-small sensor and actuator functions that can be packed into single chips, such as gyroscopes, accelerometers, magnetic field sensors, microphones, temperature and pressure sensors, and are fabricated with techniques adapted from, and sometimes co-integrated with, CMOS manufacturing. Applications range from automotive, aerospace, robotics, automation, biomedical, wearables, photonic systems and healthcare. Particular assets of advanced MEMS include functionalities such as micro/nanofluidics, soft-material polymer MEMS that are biodegradable, or transient electronics using biodegradable materials, and 3D printed elements. MEMS span size range from nanometer (scanning probes) to hundreds of micrometers. A persisting key challenge in MEMS is packaging and assembly.

Nanoengineering focuses on the development of precision processes for fabrication of a wide range of electronic/mechanical/electromechanical systems. Within this topic, we focus on the development of new tools for precision fabrication, and on the use of such tools to fabricate novel devices and systems. This is coupled with the development and utilization of new materials to enable new functionalities. These are then combined to facilitate the realization of new types of systems that are themselves miniaturized or exploit nanoscale precision to deliver their functionality. Areas of application include semiconductor devices, sensor, actuators, microfluidics, and microrobotics. As such then, in addition to serving as a core research area with IEM, this field develops capabilities that impact a broad range of IEM research areas.

Key research themes

- Nanomaterials and novel functional materials: development and exploitation of new materials for functional micro and nanosystems, with a particular focus on their functional properties. Here, we go beyond pure materials development and apply them to realization of integrated devices and systems. This theme has strong cross-cutting links to the Institute of Materials (IMX).

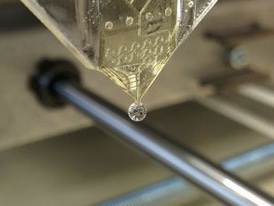

- Nanofabrication tools and processes: development of new tools and capabilities for micro and nanofabrication, with a particular focus on development of high-precision fabrication capabilities for the aforementioned classes of materials, enabling their integration.

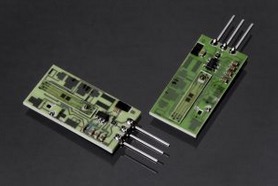

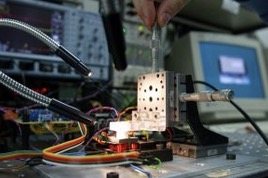

- MEMS, sensors, and actuators: development of processes and systems that exploit nanofabrication to realize devices and systems that interface with the physical world, including various classes of sensors and actuators. Topics of interest include silicon-based MEMS, polymer devices and soft systems, and devices based on nanostructured materials, including while not limited to novel sensing methods thank to smart properties at the nanoscale (e.g., the memristive effect).

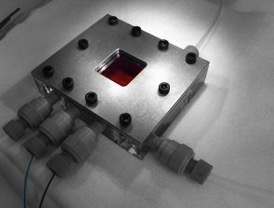

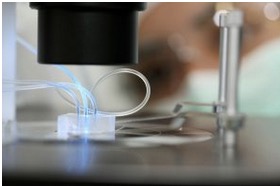

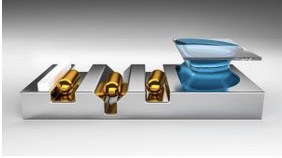

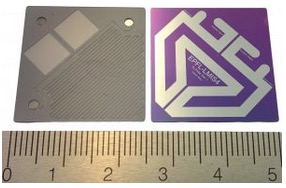

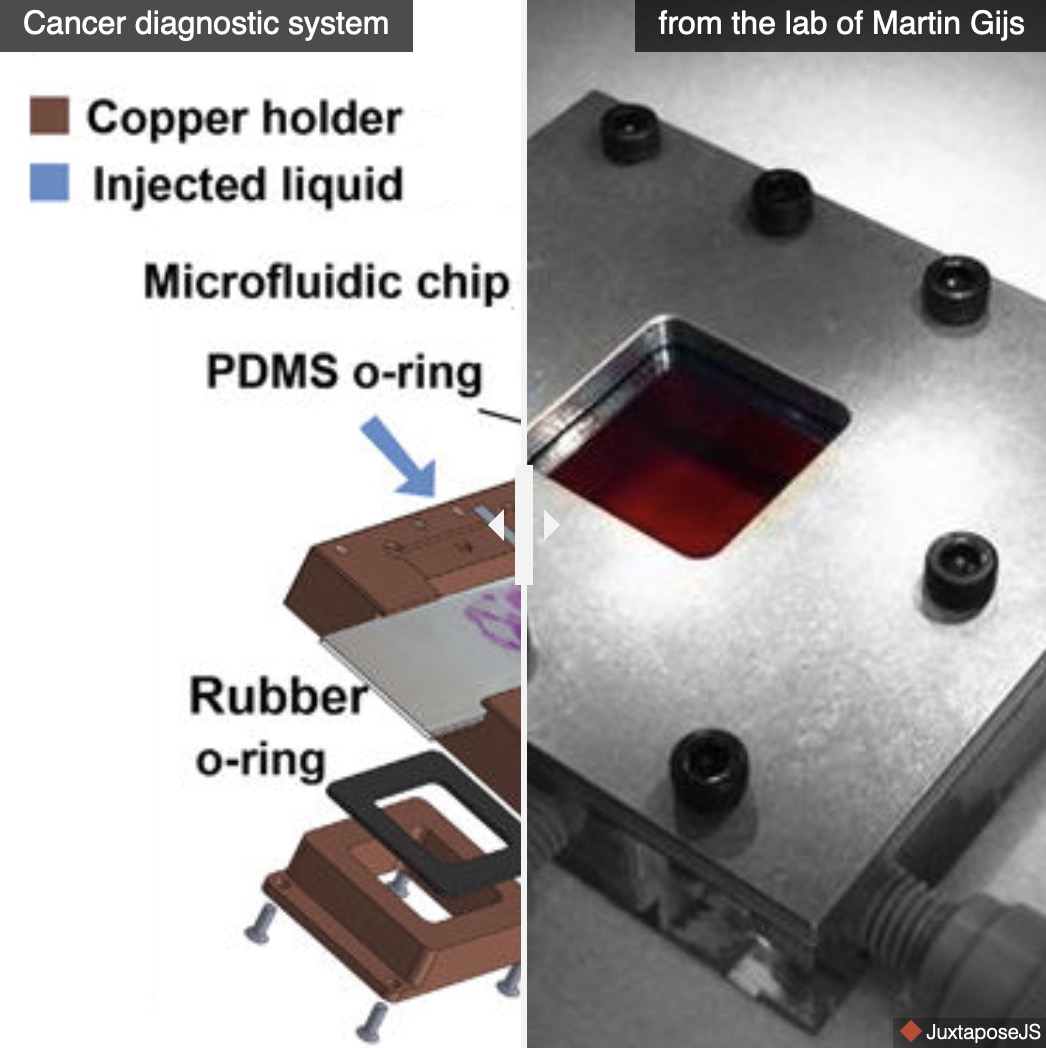

- Microfluidics and the interface to biology: exploitation of micro and nanofabrication to realize systems that manipulate and interact with fluids, and provide interfaces to biological materials. Areas of interest include realization of integrated microfluidic systems, and stimulation and recording of biological interfaces. This theme therefore has strong cross-cutting links with the broader EPFL neuro-X Institute.