Structural Materials at the Institute of Materials Science and Engineering

Mechanical properties that one aims to attain in structural materials are inherently related to their application, be it for superalloys in aircraft engines, composites used in aircraft bodies, or concrete and steel for buildings, roads and bridges. Materials scientists build an understanding of structure/microstructure-property relationships and use this knowledge to design, produce and analyse the variety of materials used in today’s many structural applications. Key to this understanding is the development and use of advanced materials characterization and of sophisticated mechanical testing methods. Advances in materials design and production rely on advances in our understanding of, and innovations in, ab-initio materials simulation and modern materials processing.At EPFL, several laboratories cover this wide spectrum of activity, with emphasis on all main structural materials classes including concrete, composite materials, ceramics or metallic materials.

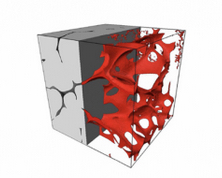

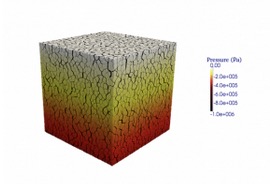

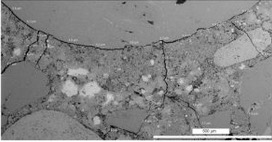

For the construction industry, particular study is being made of concrete, its role within the modern building industry and the reduction of its carbon footprint.

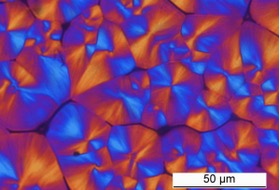

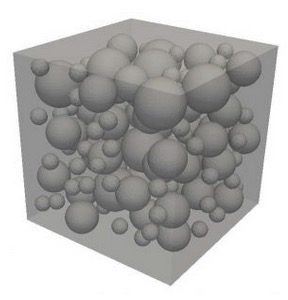

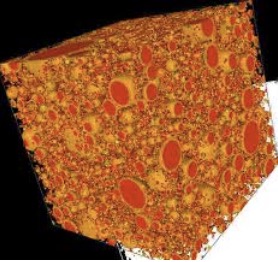

Another focus concerns advanced metallic materials, their processing and properties. Examples of such materials include metallic glasses, high entropy alloys, metal matrix composites and particle reinforced metals. Different types of thermo-mechanical processing are covered, as well as liquid metal processes. Durability of structural materials is an important aspect, often resulting from the processing, and therefore corrosion, fracture, ductility, fatigue, cracking and wear are investigated.

Structural polymer matrix composite materials are investigated, with focus on their process development, as well as on the combination of structural and functional properties by embedding sensors, actuators or enabling the material to regenerate itself after matrix damage.

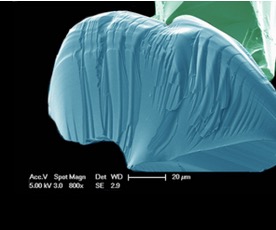

A wide range of advanced characterization techniques are used across EPFL’s laboratories, including the excellent electron microscopy facilities available in the CIME, high-precision surface analysis methods, advanced mechanical testing methods as well as the neutron / high energy X-Ray facilities that are available for EPFL researchers at the Paul Scherrer Institute.

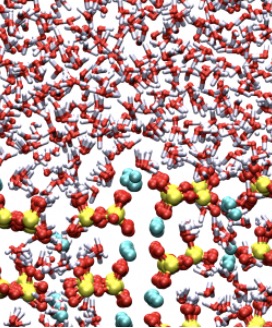

To complement the experimental techniques, modelling from the atomistic through the microstructural to the macroscopic scale gives insight into structure/property relations relevant for the application of structural materials, together with a powerful predictive capacity that enables the design of novel materials.

Key research themes

- Cementitious materials

- Microstructure design in metals, alloys and hybrid metallic materials

- Thermo-mechanical treatment

- Micromechanics

- Polymer composites

- Materials science at large scale X-ray/neutron facilities

- Tribology

- Corrosion