Machining practicals

An Essential Training Module

The machining practicals are a key milestone in your engineering journey at EPFL. This short and intensive training will allow you to master essential machining skills — a valuable asset for your future career.

What you’ll gain:

- Mastery of fundamental machining techniques

- Hands-on understanding of manufacturing processes

- Development of technical drawing interpretation skills

- Strengthened critical thinking and problem-solving abilities

Organization

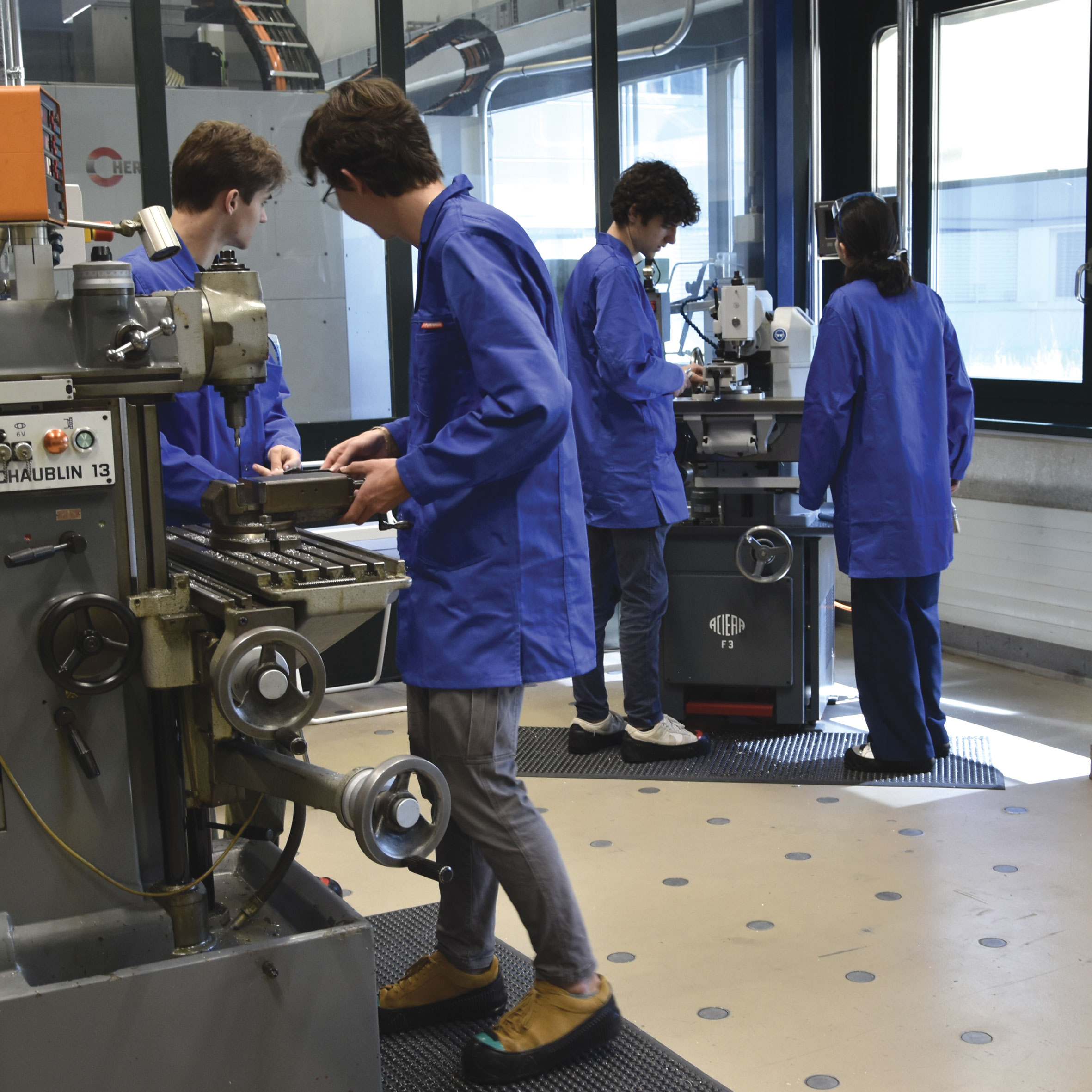

To ensure an effective learning experience, the machining practicals take place directly in EPFL’s mechanical workshops:

- Duration: 4 intensive days (3 machining + 1 fitting/assembly)

- Supervision: led by experts from the PAT (Technical Workshop Platform) and SPOT

- Ideal supervision ratio: maximum 6 students per instructor

- Workshops: ATME, ATMX, ATPR, and SPOT — all equipped with cutting-edge tools

A Flexible Schedule

Several sessions are offered to fit your academic calendar:

- March session (reserved for students going on exchange)

- July sessions (priority given to exchange students)

- August/September sessions

Registration Procedure

Registration (via MOODLE) is announced annually by email:

- ✅ Opening: early February

- ❌ Closing: end of February

- First-come, first-served basis

Eligible students:

- Students in BA4

- Students in BA6 who didn’t validate the workshop the previous year

- BA1 students advancing to BA4 after winter exams will be called the following year

Important Guidelines

- The machining practicals are mandatory to complete your Bachelor’s degree

- Students requesting an exemption (e.g., due to a completed CFC in automation) must still register and send supporting documents to smt@epfl.ch

- Any absence or delay during the workshop must be justified to Bertrand Lacour bertrand.lacour@epfl.ch

Invalidation

The workshop will be invalidated in the following cases:

- No-show

- Repeated delays

- Withdrawal without valid justification

- Dismissal due to misconduct or serious offense

Priority for Exchange Students

Students going on exchange benefit from priorityaccess to the March and July sessions.

A Hands-On Educational Project

The Gyroscope Spinner!

A project specially designed to combine theory and practice.

- A fun object you get to keep

- Concrete application of key physics concepts:

- Friction, torque, angular speed

- Rotational inertia

- Conservation of angular momentum

- Gyroscopic effect and precession

- Introduction to inertial navigation systems

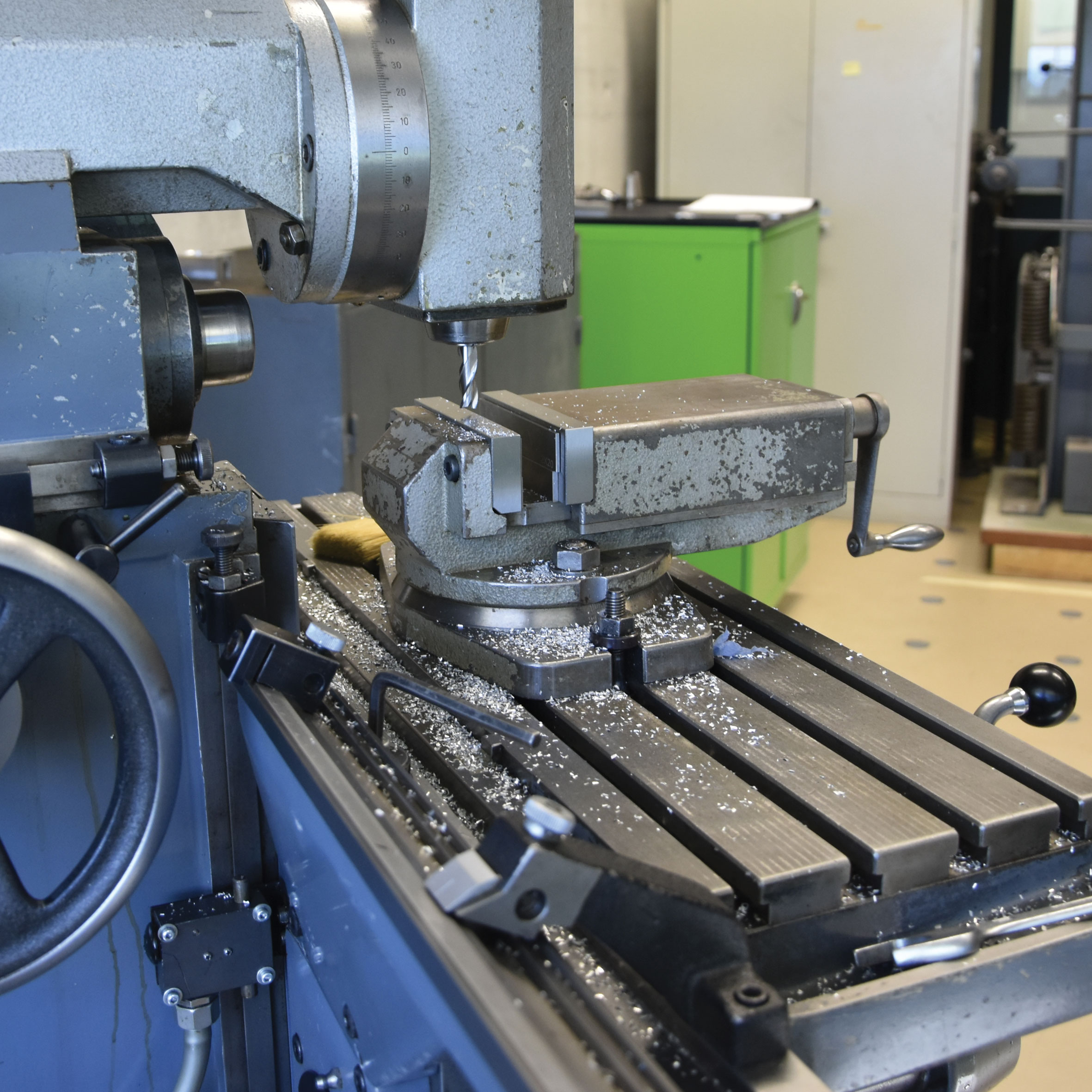

Goal 1: Master basic machining operations

You will apply several techniques using three different materials (aluminum, brass, and stainless steel):

- Facing and milling

- Turning and drilling

- Tapping

- Deburring, chamfering, and rounding

- Precision fitting

Goal 2: Learn essential assembly techniques

You will learn how to:

- Eliminate degrees of freedom and constrain movement

- Work with tolerances

- Perform different types of fits (tight and loose)

- Assemble shoulders and bearings

- Install springs and screws

This compact project lets you apply all your acquired skills while creating a functional object that illustrates core principles.

A Real and Valuable Experience

Over these four days, you’ll dive into the real world of machining and mechanical manufacturing. You’ll work in small teams on a hands-on project that allows immediate application of your theoretical knowledge.

This practical experience is mandatory to complete your Bachelor’s program.